Category: Cup Lock System

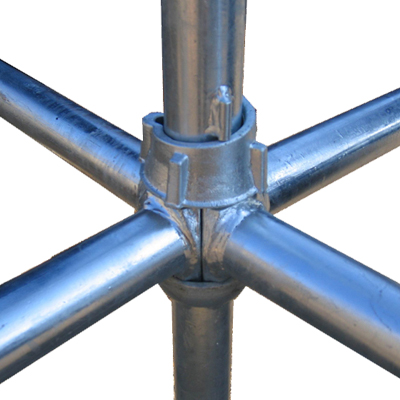

Cuplock scaffolding is a versatile and widely used modular scaffolding system in the construction industry. Its name comes from the unique locking mechanism that uses cups to secure horizontal ledgers to vertical standards.

Advantages of Cuplock Scaffolding

Fast and Easy Assembly/Dismantling: The cup and blade locking system is quick and requires only a hammer to secure connections. This significantly reduces labor time and costs.

Versatility and Flexibility: The modular design allows for adaptation to various building shapes and sizes, including straight and curved structures. Multiple ledgers can be connected at one node, offering flexibility in layout.

High Load-Bearing Capacity: Constructed from high-strength steel, Cuplock systems can support substantial loads, making them suitable for heavy-duty applications.

Safety and Stability: The secure locking mechanism and robust components contribute to a stable and safe working platform. Diagonal bracing further enhances structural integrity.

Cost-Effectiveness: While the initial investment might be higher than some basic systems, the speed of assembly, reduced labor, and reusability contribute to long-term cost savings.

Minimal Loose Parts: The captive top cups and fixed bottom cups reduce the risk of losing small components, simplifying management and ensuring all parts are readily available.

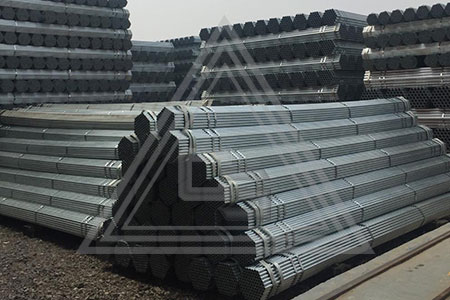

Easy Handling and Transportation: Compared to traditional tube and coupler systems, Cuplock often has fewer and lighter components, making handling and transportation more efficient.

Low Maintenance: Typically finished with hot-dip galvanization, Cuplock components are resistant to corrosion, reducing the need for frequent maintenance.