Frame Scaffolding

- Cliff Scaffoldings

- Countries

- Frame Scaffolding

Frame scaffolding systems are a versatile and widely used type of scaffolding in the construction industry. They are known for their ease of assembly, stability, and cost-effectiveness.

Key Features:

- Modular Design: Frame scaffolding systems consist of prefabricated frames that are connected together to form a stable structure. This modularity allows for easy customization and adaptability to different project requirements.

- Simple Assembly: The frames are typically connected using pins or clips, making assembly and disassembly quick and straightforward. This saves time and labor costs on the job site.

- Stability: The rigid frames and bracing system provide excellent stability, ensuring a safe working platform for workers at various heights.

- Cost-Effective: Frame scaffolding systems are generally more economical than other types of scaffolding, making them a popular choice for many construction projects.

Applications of Frame Scaffolding Systems:

- General Construction: Frame scaffolding is commonly used for a wide range of construction activities, including building erection, renovation, and maintenance.

- Masonry Work: The stability and load-bearing capacity of frame scaffolding make it ideal for supporting masons and their materials.

- Painting and Cladding: Frame scaffolding provides a safe and stable platform for painters and cladding installers to work at heights.

- Electrical and Mechanical Work: Frame scaffolding can be used to support electricians and mechanics working on building systems.

Advantages of Frame Scaffolding Systems:

- Easy to assemble and disassemble: Saves time and labor costs.

- Stable and safe: Provides a secure working platform for workers.

- Cost-effective: Generally more economical than other types of scaffolding.

- Versatile: Can be adapted to various project requirements.

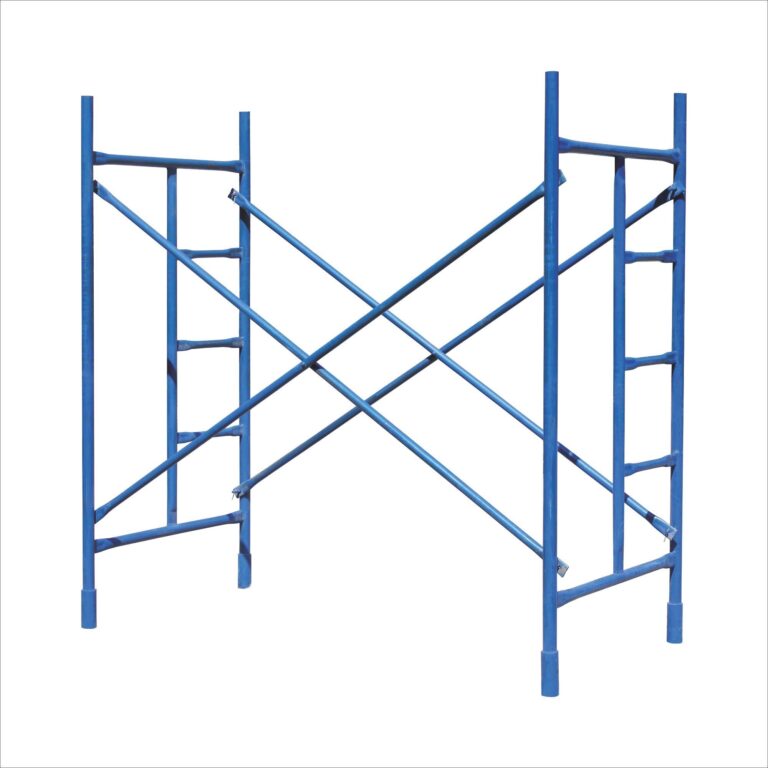

H-Frame Scaffolding

H Frame scaffolding is Ladder Type Scaffolding Frame System Used in Mason Scaffolding, Indoor Mobile Scaffold Tower Etc.

H Frame Scaffolding Components Include Vertical Main Frames, Cross Braces, Coupling Pins and Cat Walk Boards with hooks.

H Frame Scaffolding is quick erection scaffolding by main frame lock pins and cross braces. For Mobile Scaffold Tower, H Frame scaffolding used with Castor Wheels and Adjustable screw jack bases.

Please click below to get the quote

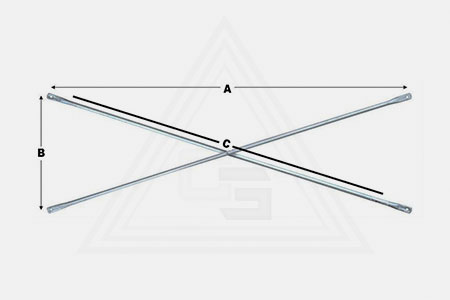

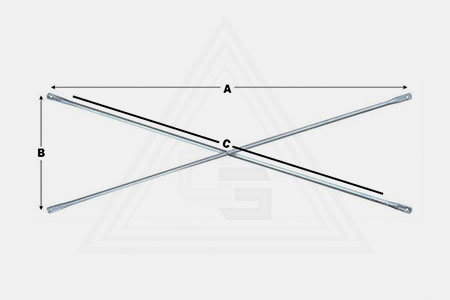

Cross Braces for H-Frame

Cross braces are diagonal members used in structural systems, such as H-frames, to provide stability and resist lateral forces like wind or seismic activity. They work by transferring loads along their length, preventing the frame from deforming.

- Materials: They can be made of various materials, including steel or aluminum depending on the application and load requirements.

- Types: Common types include X-bracing, K-bracing, and V-bracing, each with its own advantages and disadvantages in terms of strength, stiffness, and ease of installation.

- Applications: Cross braces are widely used in buildings, bridges, towers, and other structures where lateral stability is crucial.

Please click below to get the quote

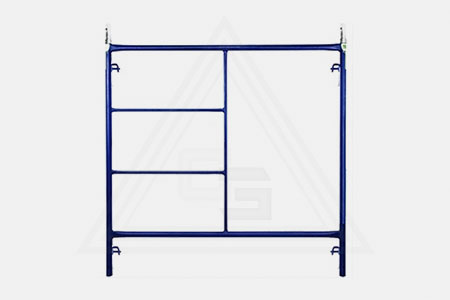

Walk Thru Frame

These are popular American Frames, however these can also be produced in any other product finish if required – Painted or Galvanized but are mainly produced in powder coated finish.

These are popular American Frames, however these can also be produced in any other product finish if required – Painted or Galvanized but are mainly produced in powder coated finish.

Please click below to get the quote

Mason Frame

A Mason Frame is a type of scaffolding frame commonly used in construction and masonry work. It’s also sometimes called a ladder frame or panel frame.

Key features of Mason Frames include:

- Ladder-like design: They have vertical posts connected by horizontal rungs, resembling a ladder.

- Stackable: They can be stacked vertically to create higher scaffolding structures.

- Versatile: They can be used with various accessories like braces, planks, and guardrails to create a safe and functional work platform.

- Durable: They are typically made of steel or aluminum for strength and longevity.

Mason Frames are a popular choice for their ease of assembly, stability, and adaptability to different project needs.

Please click below to get the quote

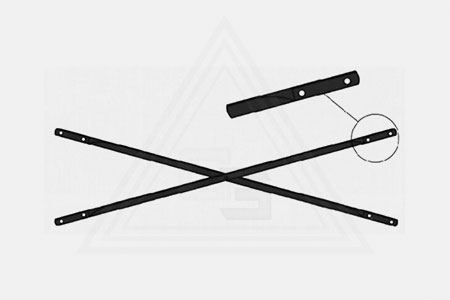

Cross Bracing

Cross braces are diagonal members used in structural systems, such as H-frames, to provide stability and resist lateral forces like wind or seismic activity. They work by transferring loads along their length, preventing the frame from deforming.

- Materials: They can be made of various materials, including steel or aluminum depending on the application and load requirements.

- Types: Common types include X-bracing, K-bracing, and V-bracing, each with its own advantages and disadvantages in terms of strength, stiffness, and ease of installation.

- Applications: Cross braces are widely used in buildings, bridges, towers, and other structures where lateral stability is crucial.

Please click below to get the quote

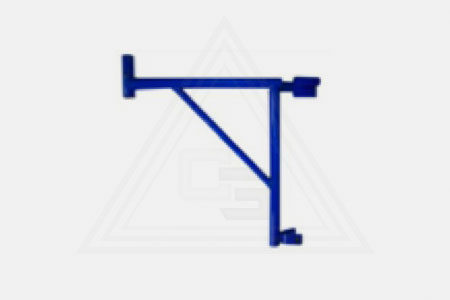

Side & End Brackets

Side and end brackets are types of brackets used in various applications, including construction, engineering, and design. They are designed to provide support and stability to structures or components.

Side brackets are typically used to support the sides of a structure or component. They are often L-shaped or have a similar design that allows them to be attached to the side of the object being supported. Side brackets can be used to support shelves, countertops, or other horizontal surfaces.

End brackets are used to support the ends of a structure or component. They are often U-shaped or have a similar design that allows them to be attached to the end of the object being supported. End brackets can be used to support pipes, rods, or other linear objects.

The specific design and dimensions of side and end brackets can vary depending on the application and the load they are intended to support. They are typically made from durable materials such as steel or aluminum to ensure they can withstand the weight and stress placed upon them.

When selecting side and end brackets, it is important to consider the following factors:

- Load capacity: The brackets must be able to support the weight of the object being supported.

- Material: The brackets should be made from a durable material that is appropriate for the environment in which they will be used.

- Size and dimensions: The brackets must be the correct size and dimensions to fit the object being supported.

- Installation: The brackets should be easy to install and should come with all necessary hardware.

By carefully considering these factors, you can select the appropriate side and end brackets for your specific application.

Please click below to get the quote

Shoring Frame

A shoring frame is a temporary structure used to support a building or other structure during construction or repair. Shoring frames are typically made of steel or aluminum and consist of a series of vertical and horizontal members that are connected together to form a rigid framework. Shoring frames are used to support a variety of loads, including concrete slabs, beams, and walls. They are also used to support excavations and other temporary structures.

Shoring frames are an essential part of many construction projects. They provide a safe and stable working platform for workers and help to ensure the structural integrity of the building or structure being constructed.

Here are some of the benefits of using shoring frames:

- They are easy to assemble and disassemble.

- They are adjustable to fit a variety of heights and widths.

- They are strong and durable.

- They are relatively inexpensive.

Please click below to get the quote

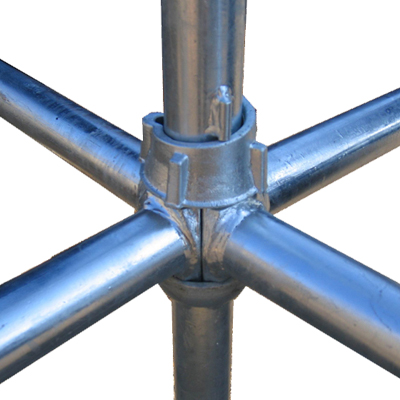

Coupling Pin - Spigots

A coupling pin, also known as a spigot, is a short metal rod that is used to join two pieces of scaffolding together. It is typically inserted into the end of one tube and then into the end of another tube, creating a strong and secure connection. Coupling pins are an essential part of any scaffolding system, and they are used to create a variety of different configurations.

Coupling pins are typically made from steel or aluminum, and they are available in a variety of sizes to fit different types of scaffolding. They are also available with a variety of different finishes, such as galvanized or powder-coated, to protect them from corrosion.

Coupling pins are easy to install and remove, and they can be reused multiple times. They are a cost-effective way to create a strong and secure scaffolding system.

Here are some of the benefits of using coupling pins:

- Easy to install and remove

- Reusable

- Cost-effective

- Strong and secure

- Available in a variety of sizes and finishes

If you are looking for a reliable way to connect your scaffolding, coupling pins are a great option.

Please click below to get the quote